CONTROL ID: 2603646

CONTACT: neil meredith

Abstract Details

CURRENT CATEGORY: Scientific

PRESENTATION TYPE: Poster

Abstract

TITLE:

Crack Arresting On Etched Titanium Dental Implant Surfaces

AUTHORS: meredith, neil

ABSTRACT BODY:

Introduction:

Etching is a common method for increasing the surface roughness of dental implants. This is typically carried out as a two stage process using Hydrofluoric acid to remove the surface oxide and a secondary acid treatment to increase surface roughness. Little consideration has been paid to a follow on treatment other than rinsing. It has been reported that such etching procedures can create cracking at grain boundaries introducing flaws that may increase the susceptibility of implants to fracture. This study compares such treatments with an alternative using a single etching stage followed by an electrical passivation process.

Method: Commercially pure Grade IV titanium implants were used in the investigation. The implant surface had been cleaned in alcohol for five hours before treatment. Implants were etched for 5 and 10 minutes at 50 degrees under ultrasonic agitation. A highly buffered 20% solution of Hydrofluoric Acid was used as the etchant. Implants were then rinsed in deionized water for 10 minutes. One group of implants were allowed to air dry and the other group were anodized at a voltage of 5 volts for 5minutes to arrest further oxidation and then dried at 50 degrees for 10 minutes. Resulting implant surfaces were examined under an SEM at 500, 1000 and 5,000 x magnification.

Results:

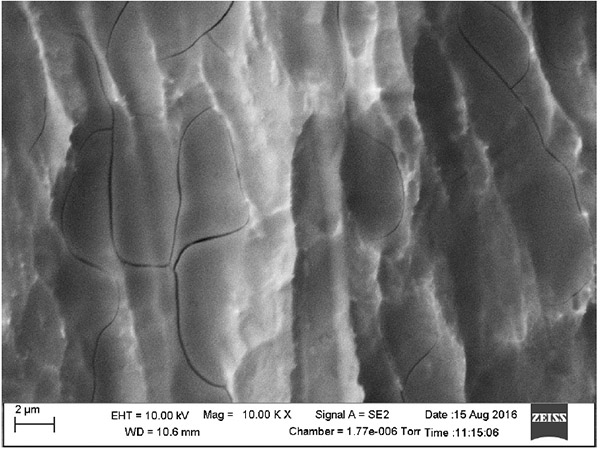

SEM examination of the treated implant surfaces revealed that the air dried group exhibited surface cracking. The anodized and oven dried group exhibited no cracking. Both surfaces had a detailed etch pattern creating an increase in surface roughness. This was especially apparent on the flanks of the screw threads.

Conclusion:

Etching titanium implant surfaces is a common method for increasing surface roughness. Such etching can lead to crack formation potentially weakening the implant body and making it more prone to fatigue failure. Cracking can be eliminated using a single stage etching process with low voltage anodization and forced drying.

Example of post etch surface cracking of titanium implant.

#SouthernImplantsAbstracts #SouthernImplantsCitings #DentalImplant #SouthernImplants